In the automotive industry’s race toward electrification, lightweighting, and zero-defect production, induction heating equipment has evolved from a supporting tool to a critical innovation engine. It directly addresses the industry’s most pressing demands—enhancing component durability, enabling dissimilar material connection,and aligning production with sustainability goals. For both internal combustion engine (ICE) vehicles and electric vehicles (EVs), induction heating equipment delivers precision, efficiency, and reliability that traditional heating methods can’t match. Let’s explore how it transforms key automotive manufacturing processes and why it’s indispensable for modern automakers.

Key Applications of Induction Heating Equipment in Automotive Manufacturing

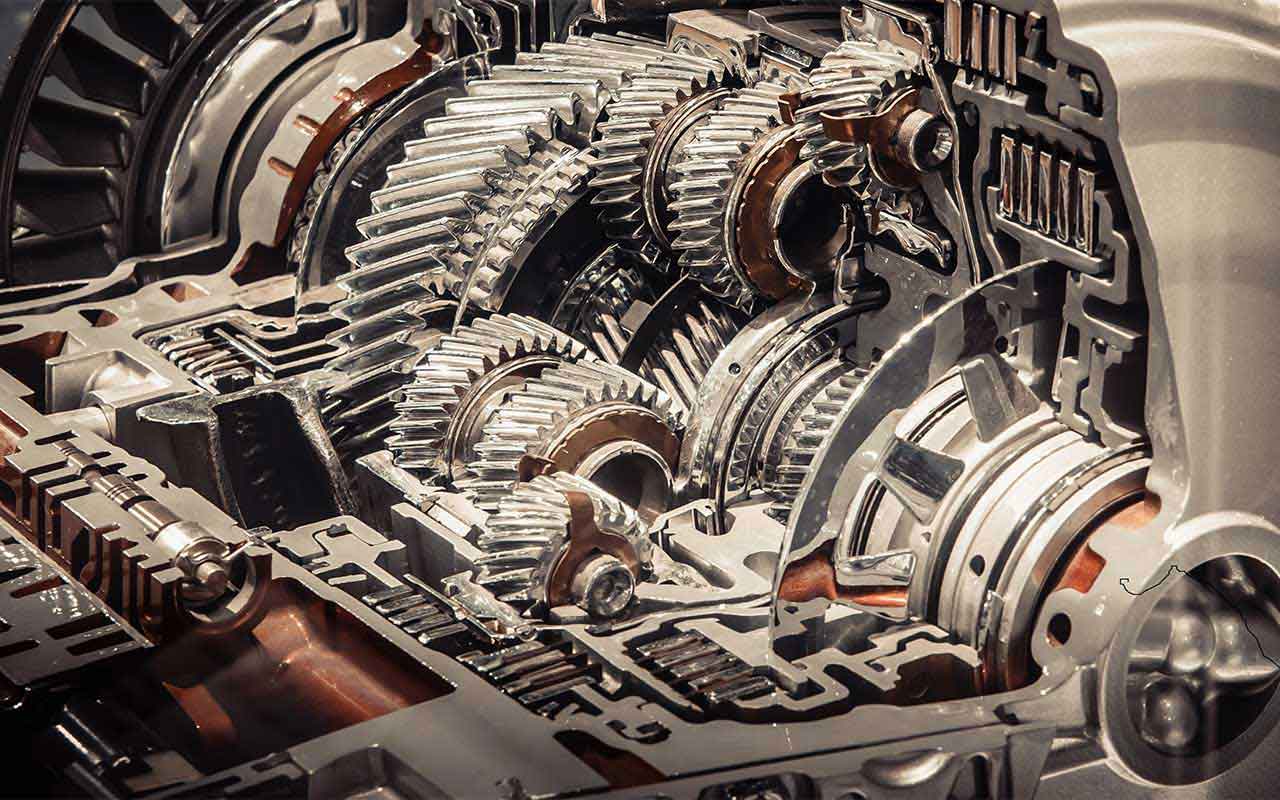

Induction heating equipment integrates seamlessly into every critical stage of vehicle production, from engine and transmission components to EV-specific parts and body structures.

1. Induction Hardening: Boosting Durability of High-Stress Components

High-load automotive parts rely on induction hardening to balance surface hardness and core toughness, extending service life and ensuring safety.

- Engine Components: Crankshafts, camshafts, and piston pins undergo induction hardening on key surfaces. This process creates a wear-resistant outer layer while preserving the core’s ductility, enabling them to withstand repeated high-speed rotation and impact loads.

- Transmission & Drivetrain: Gear teeth, drive shaft,and CV joints (constant velocity joints) require extreme wear resistance to handle torque transfer. Induction heating precisely targets these areas, preventing early wear or fracture without damaging surrounding structures.

- EV-Specific Parts: EV motor rotors, power shafts, and steering system components (ball joints, connecting rods) use induction hardening to withstand higher torque demands, a key requirement for electric drivetrains.

2. Induction Brazing: Ensuring Leak-Proof, Precision Connections

Induction brazing’s fast, localized heating makes it ideal for joining automotive components that demand airtightness and structural integrity.

- Fluid Systems: Fuel lines, cooling system fittings,and brake system high-pressure hoses rely on induction brazing for leak-proof connections. The process ensures uniform brazing filler metal flow, critical for preventing fluid leakage that could compromise vehicle safety.

- HVAC & Thermal Management: EV battery radiators, heat dissipation strips, and air conditioning aluminum pipelines use induction brazing to achieve lightweight, reliable joints. It supports efficient thermal management, a core challenge for EV performance.

- Precision Assemblies: Injector nozzles and transmission oil coolers benefit from induction brazing’s minimal heat distortion, preserving component accuracy and functionality.

3. Induction Bonding: Enabling Lightweight, High-Rigidity Body Structures

As automakers pursue lightweighting to improve fuel efficiency (ICE) and range (EV), induction bonding has become a go-to solution for joining dissimilar materials.

- Body Assemblies: Doors, hoods, and roof-side rail connections use induction heating to cure structural adhesives quickly. This replaces traditional welding, avoiding surface damage and enhancing body stiffness while reducing weight.

- Dissimilar Material Joining: Induction bonding securely connects steel, aluminum, and carbon fiber composites—common in modern vehicle bodies. It eliminates electrochemical corrosion risks and boosts collision safety by distributing stress evenly.

- Aesthetic & Functional Gains: The process avoids weld marks, creating smoother body lines, and adds sound insulation benefits, improving ride comfort.

Why Automakers Choose Induction Heating Equipment Over Traditional Methods

Induction heating equipment outperforms flame, resistance, or gas heating in key metrics that matter for automotive production:

- Unmatched Precision: Targeted heating (±1°C temperature control) minimizes component deformation and oxidation, reducing scrap rates and rework costs.

- Speed & Throughput: Reaches forging or brazing temperatures in seconds (exceeding 1,000°C for steel), cutting cycle times by 30-50% compared to traditional methods.

- Sustainability Alignment: No open flames, exhaust gases, or waste heat emission—aligning with EVs’ eco-friendly attributes and automakers’ carbon reduction goals. Energy efficiency rates of 60-90% slash utility costs.

- Automation Compatibility: Seamlessly integrates with PLCs and smart production lines, supporting Industrial 4.0 initiatives. It ensures consistent quality across high-volume manufacturing runs.

What to Look for in Automotive-Grade Induction Heating Equipment

To maximize ROI, automakers and parts suppliers should prioritize these features:

- Process-Specific Customization: Equipment should be tailored to component sizes (e.g., micro-parts like injector nozzles or large shafts), materials (steel, aluminum, composites), and production volumes (small-batch prototypes to mass production).

- EV-Focused Capabilities: For electric vehicle production, look for systems optimized for battery thermal management, motor rotor hardening, and lightweight material joining.

- Reliable Performance & Support: Industrial-grade components (durable coils, stable power supplies) ensure 24/7 operation. Partner with suppliers offering feasibility testing, installation training, and spare parts availability.

- Compliance & Safety: Choose equipment meeting automotive industry standards (ISO, IATF 16949) and safety certifications, minimizing workplace hazards from open flames or high heat exposure.

Induction heating equipment isn’t just a manufacturing tool—it’s a strategic investment for automakers navigating the shift to electrification and lightweighting. From enhancing component durability to enabling sustainable production, it solves the industry’s most complex challenges while driving efficiency and innovation.

Whether you’re producing ICE vehicles, EVs, or automotive components, the right induction heating equipment can transform your production line. Contact us today to discuss your specific process needs, request a custom solution, or schedule a live demo.